LABORATORY

Sinerlab collaborates with companies and research institutes, offering specialized XRF services for sample analysis.

Typical applications of XRF fluorescence include:

- Determination of the elemental composition of metals and alloys;

- Measurement of coatings such as Au/Ni/Cu on brass or Sn/Cu on brass;

- Decorative coatings such as Cr/Ni/Cu/ABS or Cr/Ni/Cu on brass or steel;

- Electroplated coatings such as Zn/Fe, ZnNi/Fe as corrosion protection on mass-produced parts.

Example and application

Determination of the composition of industrial alloys

Stainless Steel

The X-ray fluorescence technique allows to distinguish the different types of steel, as shown in the table below, which refers to the measurements made on samples of some of the most common types of stainless steels.

Referring only to the main constituents of the alloy, it is in fact possible to uniquely determine the type of material, and this may be useful, for example, for the rapid and non-destructive control of the raw materials.

| Name | Cr (%) | Ni (%) | Mn (%) | Mo (%) | |

|---|---|---|---|---|---|

| AISI 304 | Measured | 18,06 | 8,71 | 1,53 | - |

| Reference Value | 18,00 - 20,00 | 8,00 - 21,0 | < 2,0 | - | |

| AISI 308 | Measured | 20,95 | 10,99 | 1,00 | - |

| Reference Value | 19,00 - 21,0 | 10,0 - 12,0 | < 2,0 | - | |

| AISI 310 | Measured | 25,37 | 19,62 | 1,61 | - |

| Reference Value | 24,0 - 26,0 | 19,0 - 22,0 | < 2,0 | - | |

| AISI 316 | Measured | 17,46 | 10,94 | 1,57 | 2,01 |

| Reference Value | 16,0 - 18,0 | 10,0 - 14,0 | < 2,0 | 2,0 - 3,0 |

Precious alloys

The measurements in the table below refer to some measurements made on precious metal alloys, having the typical compositions used in the jewelery sector. X-ray fluorescence allows to quickly verify whether the legal title on the product corresponds to the actual one, providing information on the overall composition of the alloy and on the presence of chemical elements such as nickel, which in direct and prolonged contact with the skin may cause sensitization to the element itself, skin irritations, redness and dermatitis.

| Name | Measured Composition | ||||

|---|---|---|---|---|---|

| Cu (%) | Ag (%) | Au (%) | Zn (%) | Ni (%) | |

| Ag 800 | 19,85 | 80,15 | |||

| Au 18 Kt (Au 75 Cu10 Ag15) | 9,87 | 15,22 | 74,91 | ||

| Au a4 Kt | 25,5 | 59,98 | 7,14 | 7,63 | |

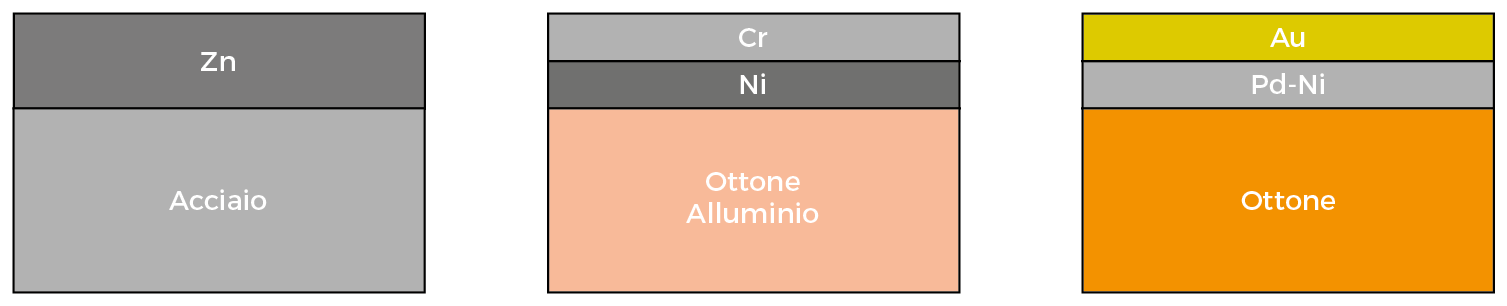

Coating thickness

Many artifacts destined to different industry sectors (eg water fittings, fashion accessories, handles, automotive, trinkets, jewelry etc.) are made of materials such as brass, aluminum or steel, and then coated by galvanic deposition of metal coatings for protection and/or decorative purpose.

Typical systems of this type are:

- Single portions of Zn, Ni, Cr, Cu, Ag, Au, Sn, ecc.

- Double portion such as Cr/Ni on Cu or brass;

- Binary alloys, such as NiPd on brass;

- Ternary alloys, such as AuCdCu on Ni;

- Ternary alloys, such as Cr/Ni/Cu on plastic or iron.

The figure below shows some of the typical coatings commonly used in the industrial field.